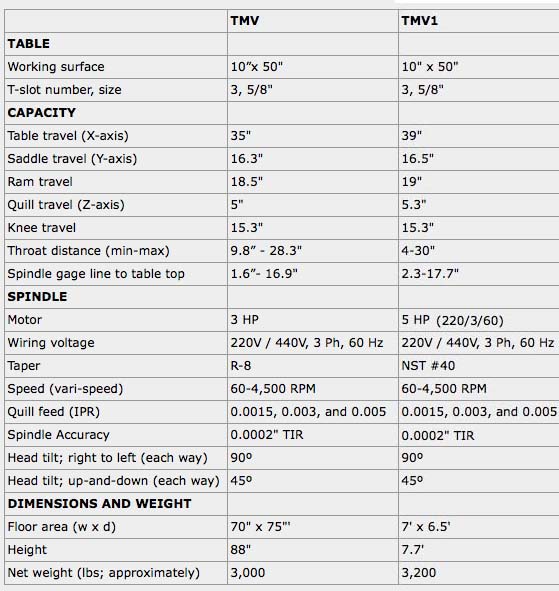

Sharp Industries 10" x 50" Table Vertical Knee Mills

These vertical knee mills are equipped with vari-speed drive, available with optional digital vari-speed. The dove tail ways chromed, and the box ways are hardened and ground.

Head

- To dissipate heat in the 3 HP motor driven head, a pair of high output fans is installed. This allows the machine to work demanding jobs for extended periods without damaging the motor, belts and bearings. A unique SHARP feature.

- The motor shaft and Vari Drive pulleys are dynamically balanced, then hard-chromed. This allows a vibration free milling even at high speed

- Since the Vari-speed drive system is operated by sliding the Vari Drive pulley up and down the motor shaft. The motor shaft is therefore chrome-plated, and has an oil channel that is fed by a grease fitting on the lower end for self-lubricating purpose. This ensures the sliding motion is trouble free at all times. A unique SHARP feature.

- The motor shaft that drives the pulley and the spindle is subject to a lot of lateral stress. A roller bearing is installed for the lower support of the motor shaft. A unique SHARP feature.

- Beside swiveling 90 degree side to side, the head can also swivel up and down by virtue of a knuckle joint design. The new design developed by Sharp uses 6 bolts, 3 each side, that fitted into a circular T-slot milled at the inside of the over arm and secured by nuts from the outside. It secured the head tightly and offered high accuracy in milling operations.

- A matched pair of super-precision ABEC-7 angular contact bearings supports the spindle. The quill is CNC-ground to a mirror finish, and then chromed to fit the housing. Together, they insure spindle run out of no more than 0.0004” TIR- the best in the industry.

Column, Table and Knee

- Hardened and ground box ways on column and saddle.

- Turcite coated slideways for better resistance to wear and retention of lube oil.

- Certified MEEHANITE castings are used for superior rigidity and better dampening of vibrations.

- Table and saddle backlash is controlled by a double-nut design that keeps the feed screw in contact with a pair of bronze nut at all times. A unique SHARP feature.

- Hardened leadscrews on table and saddle for better resistance to wear.

- The end of the table and saddle are mounted with thrust bearings that pre-load the feed screw, eliminating endplay for precisely controlled lateral movement.

- Instead of hand scraping the top of the knee ways for oil retention, the matching underside of the saddle is hand-scraped. This extra step avoids having chips and dirt embedded in the knee ways and damages the sliding area.

- "Bridgeport-style" mill

TMV1

- Hardened leadscrews on table and saddle for better resistance to wear.

- The end of the table and saddle are mounted with thrust bearings that pre-load the feed screw, eliminating endplay for precisely controlled lateral movement.

- Instead of hand scraping the top of the knee ways for oil retention, the matching underside of the saddle is hand-scraped. This extra step avoids having chips and dirt embedded in the knee ways and damages the sliding area.

Why DVS head? TMV

- High reliability with fewer moving parts than regular vari speed head

- Dynamic brake

- Low voltage control

- Large Digital rpm display

- Fully enclosed display unit

- Dependable Inverter Drive System

- Machine can run on single phase or 3 phase electricity

- Safety device prevents machine from self starting after power failure or after emergency stop being pushed

STANDARD ACCESSORIES:

- Hardened and ground box ways

- Draw bar

- Front and rear way cover

- One-shot lube system

- Toolbox with tools

OPTIONAL ACCESSORIES:

- Call for Pricing.

- Digital Variable Speed (DVS) Head

- Power feed system on table, saddle & knee

- Power draw bar

- Riser block (4" or 7")

- Right angle milling attachment

- Coolant system with chip pan

- Milling vise

- Clamping kit

- Halogen work light

- R-8 Collets