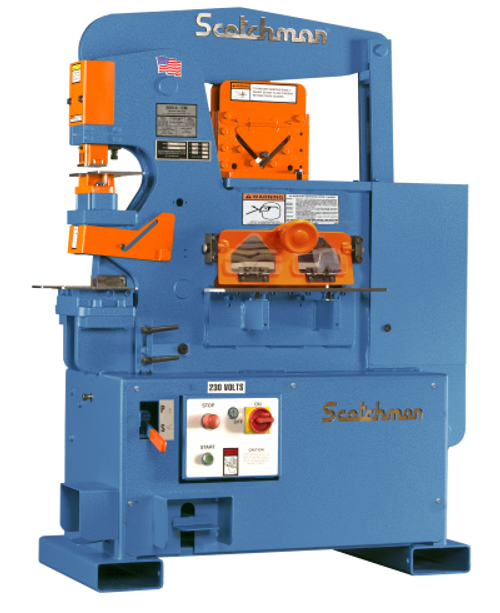

Scotchman 50-ton Ironworker - 5014-ET

The 5014 ET from Scotchman Industries is the world’s first and only 50-ton hydraulic ironworker with a 3-station turret. The innovative revolving turret accepts up to three different punch sizes that can be changed in seconds reducing set-up time and increasing productivity making the Scotchman 5014 ET ironworker the most versatile and efficient ironworker on the market. This hydraulic ironworker features 50 tons of pressure and has the ability to punch a 13/16″ hole in a 3/4″ plate and comes standard with an angle shear, 14” flat bar shear, and rectangle notcher. The 5014 ET ironworker is proudly made in the USA and is backed by Scotchman’s Best in the Business 3-year warranty.

Standard Features:

- Single Operator, 7 Stations

- 50 Ton Punch Station with 3-Station Revolving Turret (1-1/4" in 1/2" and 13/16" in 3/4")

- Keyed Punch Ram for Safety

- 4" Throat Depth

- Three 2" Die Holders, Three Punch Nuts with Wrench and Three Strippers

- One Round Punch & Die: Max. Dia. 1"

- Adjustable Electric Stroke Control with Scale

- Electric Remote Foot Pedal

- Angle Shear 4" x 4" x 3/8" at 90° and 2" x 2" x 3/8" at 45°

- 14" Flat Bar Shear with 4-Way Reversible Blade (3/4" x 4", 1/2" x 8", 3/8" x 10", 1/4" x 14")

- Rectangular Notcher, 2-1/2" x 3" x 5/16" , 2-1/2" x 2-3/4" x 3/8"

- Tool Table Work Area

- Slug Receptacle

- Electrical Box Supplied with Emergency Palm Button and Lock-out Tag-out Accommodations

- 230/460 volt /3 Phase Electrics (must specify voltage)

- All Guards Necessary to Comply with ANSI B 11-5 Standards

- Forklift Accommodations

- Warranty: Three Years on Parts

- Made in USA

Specifications:

| Rated on: | 65,000 PSI Tensile | A 36 Mild Steel |

| Punching Capacity | 50 ton 1-1/4" in 1/2" 13/16" in 3/4" |

45 mt 32 mm in 12 mm 21 mm in 18 mm |

| Special Tooling | 2-1/4" Max. Dia. | 57 mm Max. Dia. |

| Throat Depth | 4" | 100 mm |

| Flat Bar Shear | 14" Length 3/4" x 4" 1/2" x 8" 3/8" x 10" 1/4" x 14" |

350 mm 18 mm x 100 mm 12 mm x 200 mm 10 mm x 250 mm 6 mm x 350 mm |

| Opt. Saber Blade | 1/2" x 10" 3/8" x 12" |

12 mm x 250 mm 10 mm x 300 mm |

| Angle Shear 90° | 4" x 4" x 3/8" | 100 mm x 100 mm x 10 mm |

| Angle Shear 45° | 2" x 2" x 3/8" | 50 mm x 50 mm x 10 mm |

| Brake 8" | 25 ton | 23 mt |

| Brake 12" | 25 ton | 23 mt |

| Open End Brake | Max. 1/4" x 3" Flat or Angle Iron |

(6 x 76 mm) |

| Pipe Notcher Schedule 40 I.D. |

3/4" 1" 1-1/4" 1-1/2" 2" |

19 mm 25 mm 32 mm 38 mm 50 mm |

| Rectangle Notcher | 2-1/2" x 3" x 5/16" 2-1/2" x 2-3/4" x 3/8" |

62 mm x 75 mm x 8 mm 62 mm x 69 mm x 10 mm |

| 90° V. Notcher | 6" x 6" x 1/8" 3" x 3" x 1/4" |

150 mm x 150 mm x 3 mm 75 mm x 75 mm x 6 mm |

| Strut Shear | Samples Required | |

| Rod Shear Round Rod (Max.) Square Rod (Max.) |

1/4" to 1" 5 Cavity 7/16", 9/16" 5/8", 3/4", 1" 1/4" to 3/4" 1 Cavity 3/4" |

6 mm to 25 mm 11 mm, 14 mm 16 mm, 19 mm, 25 mm 6 mm to 19 mm 19 mm |

| Square Tube Shear | 1/2" to 1" 12 ga. |

12 mm to 25 mm 2.75 mm |

| Picket Tool | 1/2" 3/4" 1" 16 gauge |

12 mm 19 mm 25 mm 1.6 mm |

| Strokes Per Minute in Light Material [Punch Station] |

1/4" stroke | 40 spm |

| Strokes Per Minute in Heavy Material [Punch Station] |

3/4" stroke | 17 spm |

| Hydraulics | 2100 psi | 145 bar |

| Motors Standard | 3 hp 3 ph 230/460 208/380/575 |

2.24 kW |

| Motors Optional | 5 hp 1 ph 220v |

3.73 kW |

| Dimensions | W-23" L-48" H-70" |

W-59 cm L-122 cm H-178 cm |

| Shipping Weight | 1,580 lbs | 717 kg |