Royal High Speed Precision Live Centers

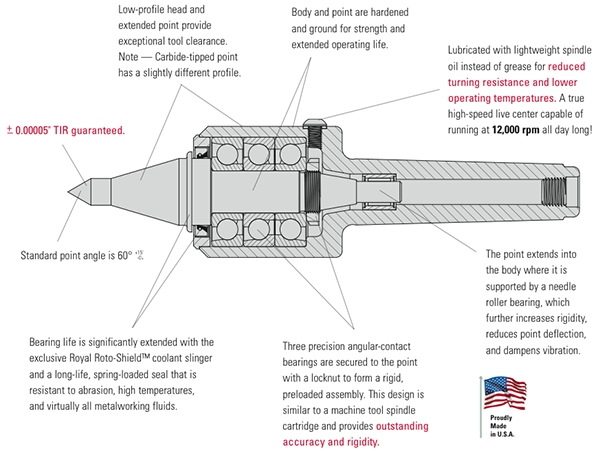

- The Royal High Speed Precision Live Center is a true high-speed live center - up to 12,000 rpm.

- The Royal High Speed Precision Live Center is lubricated with lightweight spindle oil instead of grease for reduced turning resistance and lower operating temperatures.

- The extended point of the Royal High Speed Precision Live Center, available in both steel and carbide-tipped versions, has been optimized to provide high rigidity and outstanding tool clearance.

- The Royal High Speed Precision Live Center is extremely accurate, with runout guaranteed to +/- 0.00005” TIR or better.

- Bearing life is significantly extended with the exclusive Royal Roto-Shield coolant slinger and upgraded, long-life, spring-loaded seal that is resistant to abrasion, high temperatures, and virtually all metalworking fluids.

- This live center model incorporates three precision angular-contact bearings that are secured to the point with a locknut to form a rigid preloaded assembly. This design is similar to a machine tool spindle cartridge and provides outstanding accuracy and rigidity.

- The point of the Royal High Speed Precision Live Center extends into the center's body where it is supported by a needle roller bearing. This further increases rigidity, reduces point deflection, and dampens vibration.

- The low-profile head of the Royal High Speed Precision Live Center offers exceptional tool clearance.

- Both the point and body of this live center model are hardened and ground for strength and extended operating life.