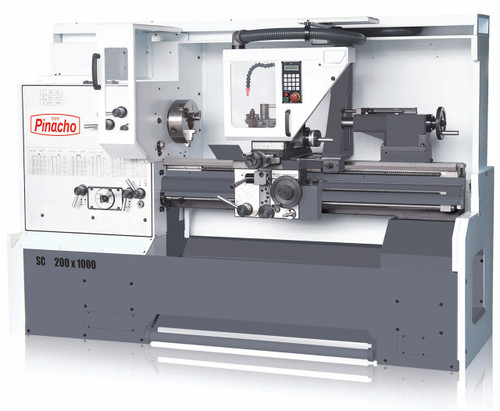

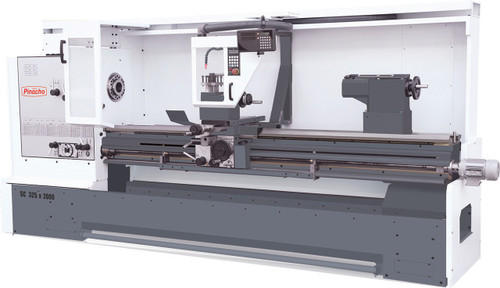

Metosa/Pinacho Lathes Series SC

The combination of constant surface and electronically variable spindle drive SC gives the better cutting performance among the best lathes in the market. Combination of precision, power, durability and advanced features ensure long-living performance. SC - the state of the art technology makes it ideal for tool room and production applications with maximum precision, high productivity, long life to the machines.

Features:

- Constant power, 3 range variable speed

- Ease of use and excellent assistance for high accuracy jobs

- High chip removal rate during the rough turning operation

- Induction Hardened & grounded guide ways

Benefits:

- Very versatile for machining big and small components

- Constant power in all RPM ranges

- Very high production efficiency

- Excellent quality finish with maximum precision

Standard Accessories:

- Spindle brake

- Main spindle reducing bush & fixed centre

- Tailstock reducing bush & fixed centre

- Square tool post and key

- Chip collecting tray

- Instruction manual

- Centralised lubrication

- Coolant equipment

- Reducing bush

- Rear splash guard

- Top Slide guard

- Rigid lead screw guard

- Levelling plates

- Chuck guard with limit switch

- Emergency stop

- Main switch

- Work light

- C E Compliant

Specifications:

| Model | SC200 | SC250 | SC325 |

| Centre distance | 30" / 40" | 40" / 60" | 40" / 60" / 80" / 120" |

| Centre height | 8" | 10" | 13" |

| Swing over bed | 16" | 20" | 26" |

| Swing over gap | 22" | 27-1/2" | 36" |

| Gap length in front of face plate | 5" | 6" | 9" |

| Bed width | 10" | 12" | 14" |

| Swing over carriage | 13" | 17" | 23" |

| Swing over cross slide | 9-1/2" | 12" | 18" |

| Cross slide travel | 8" | 9-3/4" | 12-3/4" |

| Tool post slide travel | 4" | 5" | 6" |

| Maximum tool dimensions | 3/4" x 3/4" | 1" x 1" | 1" x 1" |

| Headstock Main spindle bore | 1-1/2" | 2-1/2" / 4" | 3" / 6" |

| Main spindle nose / Camlock | A2 - 5 / 5 | A2 - 8 / 8 | A2 - 11 / 11 |

| Main spindle morse taper (MT) | 4 | 4 | 5 |

| Speed range (rpm) | 40 - 2800 | 40 - 2300 | 30 - 1700 |

| No. of speed range | 3 | 3 | 3 |

| Speed range 1 (rpm) | 40 - 345 | 85 - 200 | 50 - 120 |

| Speed range 2 (rpm) | 345 - 1015 | 200 - 465 | 120 - 290 |

| Speed range 3 (rpm) | 1015 - 2800 | 465- 1250 | 290 - 800 |

| Norton box No. threads and feeds | 44 | 44 | 55 |

| Longitudinal feeds | 0.05 - 0.752 | 0.05 - 0.752 | 0.05 - 1.5 |

| Cross feeds | 0.025 - 0.376 | 0.02 - 0.296 | 0.025 - 0.752 |

| Metric threads | 0.5 - 7.5 | 0.5 - 7.5 | 0.5 - 15 |

| Whitworth threads in T.P.I | 60 - 4 | 60 - 4 | 60 - 2 |

| Modular threads | 0.25 - 3.75 | 0.25 - 3.75 | 0.25 - 7.5 |

| Pitch diametral threads | 120 - 8 | 120 - 8 | 120 - 4 |

| Ø35 lead screw rod pitch | 1/4" | 1/4" | 1/4" |

| Tail stock barrel diameter | 2-1/4" | 2-1/2" | 3-3/4" |

| Tail stock barrel travel | 7" | 7-3/4" | 8-1/2" |

| Tail stock morse taper (MT) | 4 | 4 | 5 |

| Fixed Steady capacity | 4-3/4" | 5-1/2" | 7-1/4" |

| Follow Rest capacity | 3-1/2" | 3-3/4" | 5" |

| Main Motor Power (kw) | 4 | 5.5 | 7.5 |

| Pump Motor Power (kw) | 0.1 | 0.1 | 0.1 |

| Capacity of coolant tank (Lts) | 42 / 55 | 67 / 92 | 81 / 111 / 151 / 201 |

| Overall Dimensions | |||

| Length | 83" / 94" | 106" / 126" | 106" / 126" / 150" / 185" |

| Width | 36" | 37" | 43" / 44" |

| Height | 64" | 69" | 72" |

| Weight (lbs.) | 2491 / 2624 | 3351 / 3704 | 3858 / 4630 / 5512 / 6835 |

| Acceptance Accuracy | DIN 8605 | DIN 8605 | DIN 8605 |