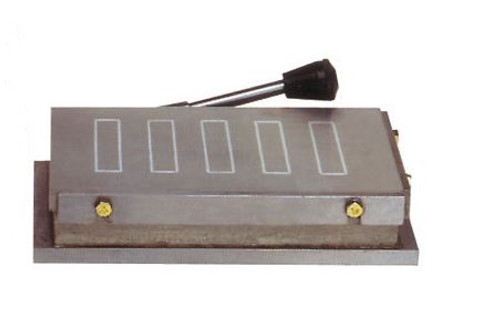

Knuth Plasma-Jet DSL, 5 x 10 ft. Table

World-Class Plasma Cutter Systems based on the know-how and technology of the market leader Hypertherm®

Features:

- PREMIUM cutting systems come in a wide variety of equipment packages featuring up to 6-axis cutters

- Selection of the optimum Hypertherm® plasma source

- Hypertherm MicroEDGE® Pro CNC control & software package

- Extremely rigid design for maximum cutting precision

- Dual-drive bridge

- High-quality linear guides on all axes

- Dynamic AC servo drives on all axes with maintenance-free, zero-backlash planetary gears

- Low-wear and low-maintenance helical gears are designed for continuous operation

- Optimum track speed even for fine contours and tight radii

- Automatic torch height control

- Stand-alone cutter table features rigid steel construction for high load capacity

- Adjustable cutting current

- Stand-alone table eliminates thermal and mechanical influences on the plasma cutter system

- Quick-coupling for cutter head changes in seconds

- Minimized tooling time ensure maximum cost savings

- Use the existing cutting parameters stored in the control to find the optimum cut

- Available with 5-axis cutter head, tube cutter, and many more options

Control:

Hypertherm® MicroEDGE Pro®

Increased quality and productivity for reduced cost using an advanced control technology!

- HyDefinition cut quality

- Automatic kerf-width compensation according to material thickness, current and speed

- Automatically adjusted plunge-cut and cutting height ensure maximum service life of wear parts

High user comfort

- Offline software automatically sets up the cutting process parameter

- Easy configuration of orders with CutPro Wizard

- User prompts to enter board type and wear part number

- Tips for cutting optimization

- Operator manual for CNC, torch height control and plasma source on the operating display

- Diagnostics via Internet

- Offline diagnostics via form requisition/CNC software for the parts program

Standard Equipment:

- Operating system: Windows

- Industrial PC with 15" touch-screen monitor

- Graphical user interface

- USB port

Technical Data:

| Working area | |

| Rapid feed | 1181 in/min |

| Table height | 31 in |

| Table load capacity | 205 lbs/ft2 |

| Cutting Length | 120 in |

| Cutting Width | 63 in |

| Distance between cutter head and table | 7 in |

| Cutting capacity in steel alloy | |

| Hole cutting capacity in production | 0.8 - 2 in |

| Cut-off (edge-start) | 1- 3 in |

| Cutting capacity in plain carbon steel | |

| Virtually burr-free | 0.6 - 1.5 in |

| Hole cutting capacity in production | 0.9 - 2 in |

| Cut-off (edge-start) | 1.5 - 3 in |

| Measures and weights | |

| Weight | 6505 lbs. |

Plasma-Jet DSL Standard Equipment:

- Hypertherm® MicroEDGE® Pro CNCg

- Hypertherm® plasma source

- Hypertherm® cutter head

- Hypertherm® Nestmaster® nesting software

- Z axis with servo-THC

- Magnetic torch coupler, work table with vacuum connector and automatic shutter control

- Operator manual

- Programming instructions

Knuth Plasma-Jet DSL, 5 x 10 ft. Table