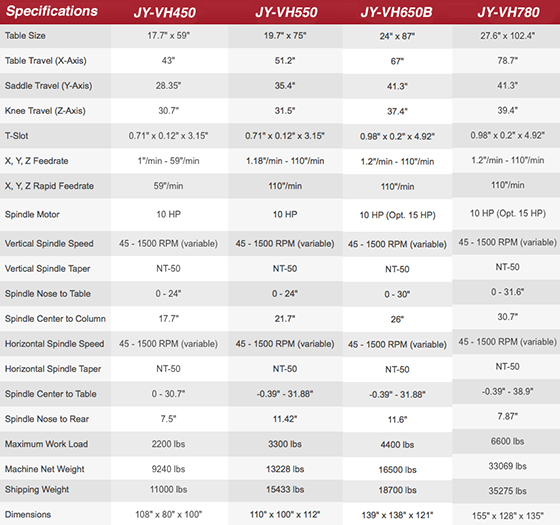

Kent Combination Horizontal and Vertical Spindle Milling Machines

Kent USA Combo H/V Mills offer both the capabilities of a Vertical Mill and a Horizontal Mill in one design. Changing the setup from one operation to the other is quick and simple. These mills are equipped with hard-chromed dovetail ways or hardened and ground box ways for superior wear resistance and separate motors drive the vertical spindle and horizontal spindle.

- 10 HP spindle motor infinitely variable speed, #50 taper spindle, 17.7” x 59” hardened and ground table top

- Saddle and base with hardened and ground square (box) ways

- Precision ACME screws in X, Y, & Z axes

- X, Y, & Z axes driven by AC motor

- Precision bored and ground milling head, with super precision ABEC-7 bearings

- Meehanite® casting, with built in coolant reservoir in machine base

- Coolant system and chip tray

- Centralized automatic lubrication, with metered check-valves

- Precise angular contact bearings spindle

- Precision manufactured from SCM21 alloy steel, heat treated and precision ground spindle

- Hardened and precision ground for quiet running gears

- High torque servo motor X-axis feed

- Choice of Fanuc or Mitsubishi CNC controller

- Hardened, precision ground, and Turcite-B coated sideways for maximum wear resistance

- Convertible into CNC controlled system

Optional Accessories

- Dro System

- Air Power Drawbar (Per Spindle)

- Angle-Lock Vice

- Rotary Table (Vertical and Horizontal)

- Clamping Kit

- Chuck System

- Rustlick Coolant (1 Gal, Mixes 1:30)