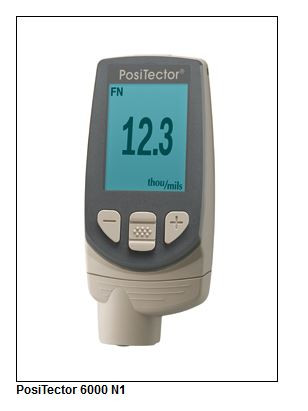

Defelsko PosiTector 6000 Coating Thickness Gages with N Probe

The PosiTector 6000 N1 includes a Standard(1) gage body and a removable built-in N probe for measuring non-conductive coatings on non-ferrous metal substrates (aluminum, copper, etc.). Ideal for one-handed operation.

The PosiTector 6000 N3 includes a Advanced(3) gage body and a removable built-in N probe for measuring non-conductive coatings on non-ferrous metal substrates (aluminum, copper, etc.). Ideal for one-handed operation.

Click for Probe Details / Ordering Guide

Simple:

- Ready to measure-no calibration adjustment required for most applications

- One-Handed menu navigation

- Bi-color indicator light-ideal in a noisy environment

- RESET feature instantly restores gauge to factory settings

Durable:

- Solvent, acid, oil, water and dust resistant - weatherproof

- Wear-resistant probe tip

- Shock-absorbing, protective rubber holster with belt clip

- Two (2) year warranty on gage body and probe.

Accurate:

- Certificate of Calibration showing traceability to NIST included

- Built-in temperature compensation ensures measurement accuracy

- Hi-RES mode increases gages displayed resolution for use on applications that require greater precision

- Conforms to national and international standards including ISO and ASTM

Versatile:

- Fully interchangeable probes are compatible with ALL gage bodies

- Multiple Calibration adjustment options including 1 point, 2 point, known thickness, average zero

- Selectable display languages

- Hi Contrast backlit display for bright or dark environments

- Flip display enables right-side-up viewing

- Extended cables available (up to 75 m/250 ft) for underwater or remote measuring

- Uses alkaline or rechargeable batteries (built-in charger)

| Feature Comparison Chart | Standard(1) | Advanced(3) | |

| Order Code (includes Standard(1) Gage body and N Probe) | N1 | N3 | |

| Included Probe | N | N | |

| Accepts all PosiTector 6000 probes | X | X | |

| All features shown on Overview page | X | X | |

| Hi Contrast reversible color LCD | X | ||

| FAST mode - faster measurement speed for quick inspection | X | X | |

| SCAN Mode - take continuous readings without lifting the probe | X | ||

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits | X | X | |

| Statistics - Instantly calculate average, standard deviation, min/max thickness and number of readings while measuring | X | X | |

| Reading Storage Capacity | 250 in one group | 100,000 in up to 1000 groups | |

| USB port for fast, simple connection to a PC and to supply continuous power. USB cable included | X | X | |

| USB mass storage - stored readings and graphs can be accessed using universal PC/Mac web browsers or file explorers. No software required | X | X | |

| Connects to PosiTector.net | X | X | |

| SSPC PA2 feature set determines if film thickness over a large area conforms to user-specified min/max levels | X | ||

| PSPC 90/10 feature determines if a coating system complies with an IMO performance standard for protective coatings | X | ||

| Wireless Technology for data transfer to a PC or optional portable printer | X | ||

| Real Time Graphing | X | ||

| Onscreen help, picture prompting and batch notes | X | ||

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | X | ||

| Two (2) Year Warranty on Gage and Probe | X | X | |

| N Probe (included) | ||||

| Range: | 0 - 1500 um 0 - 60 mils | ||

| Accuracy*: | + (0.05 mils + 1%) 0 - 2 mils + (0.1 mils + 1%) > 2 mils | |||

| + (1 um + 1%) 0 - 50 um + (2 um + 1%) > 50 um | ||||

| *Accuracies are stated as a fixed value plus a percentage of the gage's actual reading. | ||||

| Comes complete with Standard(1) gage body, N probe, precision plastic shims, protective rubber holster with belt clip, wrist strap, 3 AAA alkaline batteries, instructions, nylon carrying case with shoulder strap, protective lens shield, Long Form Certificate of Calibration traceable to NIST, USB cable, two (2) year warranty. Size: 137 x 61 x 28 mm (5.4" x 2.4" x 1.1") Weight: 140 g (4.9 oz.) without batteries CONFORMS TO: ISO 2178/2360/2808, PrEN ISO 19840, ASTM B499/D1186/D1400/D7091/E376/G12, BS3900-C5, SSPC-PA2 and others |