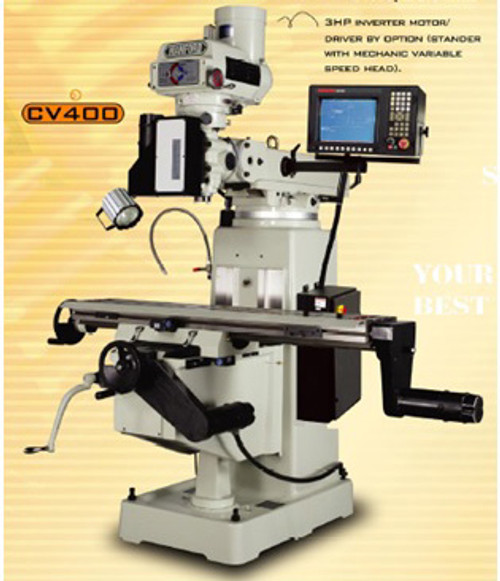

Manford CNC Turret Milling Machine CV-400 w/ Fagor Controller

Features:

- 10" X 54" Table

- Variable speed, 3HP, 3 Phase, 220/440V

- R8 or NST#30 Spindle material SAE4115(SCM415) full piece by hardened & ground

- Turcite-B On XY ways, slideways & Gibs

- Hardened & Ground X&Y Slideways and table

- 32mm Precision ground Ball screws on XY

- Grinding on Ram & column slideways

- Grinding on table T-slot

- Hardened & ground on Quill

- Leveling Screw & Plate On Base.

- Strict Required Scraping with High Precise Accuracy.

- Tool box & Tools

- Rubber chip cover (front & rear)

- Auto Lubrication system

- Work light included

CV-400 Fagor 8055i-FL 3 axis CNC Complete Package Includes:

- 24 VDC power supply

- Logic relays for M3, M4, and M8

- 16 inputs and 8 outputs

The Operator station will contain:

Compact Color LCD Monitor and Keypad with available keys for customization

- 3 Axis 8055-FL Mill Control (Control has4th axis capability with option)

- 10.4 inch Color LCD screen

- Conversational (ICON) / G-Code Programming

- Memory: 500MBof memory card (expandable)

- Solid Graphics

- Customizable screen and software

- Profile Editor

- Fast Block Processing Speed

- USB Port and RS232 for Program Management

- WINDNC communication software

- TeleDiagnosis: Access and Control CNC via internet (Optional)

- PLC 16 Inputs/8 Outputs

- Relays: Spindle on/off M3/M4, coolant on/off M8, emergency button E-Stop

- Ethernet (Optional)

Servo Drive System

- (3) 31 in/lb. stall torque

- (3) Drives

- (3) 10 or 12 meter servo cables

All FAGOR AUTOMATION components are CE Certified

All 8055-FL electronic packages include a full One-year warranty

Optional Accessories:

- Coolant system

- Coolant tray (base)

- Hardware limit switch for 2 axes (included)

- Air Power Drawbar (R8 or NST#30)

- EVS head with 3 HP Inverter motor and Driver

- Align Power feed on Z option

- Servo Turbo Power feed on Z option

- Transformer for power to 220V requiredfor inverter & CNC (Required if power supply is other than 220V, 3 Phase)

- Side splash guard 2pcs

- Coolant Mist unit stand alone

- MPG manual Pulse Generator: hand jog remote

- Riser block 4" / 6" / 8"

Control Options:

- UFO Flat Handwheel on the side of the Operator Panel

- Conversational Programming (standard)

- Telediagnosis

- DNC (winddnc) (standard)

- Engraving

- Speed Feed Assistance

- Solid Graphics (standard)

- 2 GB Compact Flash

- Ethernet

- Digitizing Software

Special Options:

- 4th axis Drive - 4th Axis DC Driver

- Additional I/O (54IN 31OUT) with 8 Spare M Functions - Additional PLC inputs and outputs (includes wiring & Labor)

- ADD REMOTE START/STOP SWITCH - REMOTE PENDANT AUXILIARY START/STOP SWITCH WITH 6 FT CABLE

Specifications:

| Table | 10" x 54" |

| T-slot No. x Size | 3 x 5/8" |

| Longitudinal Travel | 32-5/8" |

| Cross Travel | 15" |

| Travel of Knee | 14" |

| Travel of Z axis (Quill) | 4.5" |

| Ram Travel | 22" |

| Table to Spindle Nose | 5-7/8" - 9-7/8" |

| Over Swivel on Turret | 360° |

| Swiveling Angle and Head (R & L) | 90° |

| Head Tilt (Up & Down) | 45° |

| Spindle to Column | 6-1/4" - 28-1/4" |

| Spindle Motor | 3HP, 3 Phase, 220/440V |

| Spindle Taper | R8 (NST#30 option) |

| Longitudinal/Cross Feed Rate | 0 – 120 in/min |

| Quill Feed | 0.0015" - 0.003" - 0.006" |

| Spindle Speed (RPM) | (60Hz) 60-4500 |

| Dimensions (LxWxH) | 72-7/8" x 74-3/4" x 83-1/2" |

| Net Weight | 3080 lbs. |

Manford CNC Turret Milling Machine w/ Fagor Controller