MeasurLink An Integrated Solution for Quality Data Management-64AAS921D

FEATURES:

- SPC Data Analysis Software for Windows®

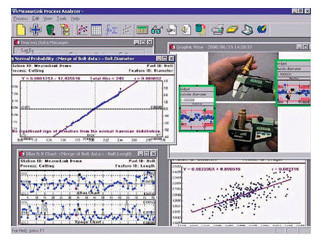

- MeasurLink® SPC Process Analyzer is an invaluable tool for your quality team.

- It gives you the flexibility to analyze your processes, identify problem areas and take corrective action to improve your product’s quality.

- Inspection runs can be sorted by Inspection Station, Process or Part, and are displayed with the look and feel of the Windows Explorer.

- Inspection data can be merged, filtered, grouped, charted and printed in the way you want it.

- MeasurLink® SPC Process Analyzer gives the QC Engineer a spreadsheet interface option and allows math calculations on inspection data.

- With the ability to import/export ASCII file data, MeasurLink® SPC Process Analyzer can port to or from other applications with ease.

- Capability vs. time, capability vs. traceability and ”what if” scenarios are all available in Process Analyzer.

- Correlation studies with regression analysis and normality plots are available.

- A comprehensive spreadsheet display is available that offers the engineer detailed summary reports both within a production run and between multiple runs.

- This application is ideal for our customers to generate reports for their customers and also to isolate areas for corrective action within their own manufacturing process.

- Process Analyzer has additional view types to provide more information to the engineer.

- The multi-variant view super-imposes related characteristics to check for time based correlation.

- Capability vs. Traceability can be used for machine or operator comparisons. Capability vs. Time can be used for tool wear predictability.

MeasurLink An Integrated Solution for Quality Data Management-64AAS921D