Exair High Power Cold Gun, no included hose outlets

A new solution to an old problem. Heat build up on dry machining operations reduces tool life and machining rates. The Cold Gun Aircoolant System produces a stream of clean cold air at 50°F (28°C) below supply air temperature.

Operation is now a quiet 82 dBA and there are no moving parts to wear out. It will remove heat to prolong tool life and increase productivity on machining operations when liquid coolants cannot be used.

The Cold Gun is also an alternative to expensive mist systems. It eliminates the costs associated with the purchase and disposal of cutting fluids and worker related health problems from breathing airborne coolants or slipping on wet shop floors.

EXAIR's Cold Gun is non-adjustable to prevent freeze-up during use. Cold airflow and temperature drop are factory set to optimize the gun's cooling capability.

The Cold Gun increases tool life, tolerances and production rates by eliminating heat build-up. The quiet Cold Gun produces cold air at 20°F from compressed air to extend tool life, stop burning, and reduce wheel loading. No moving parts assures maintenance-free operation. The Cold Gun is ideal for dry machining or to replace messy mist systems.

Applications:

- Tool sharpening

- Drill and cutter grinding

- Routing

- Plunge and form grinding

- Milling

- Surface grinding

- Drilling

- Tire grinding

- Band sawing

- Plastic machining

Cold Gun Advantages

- Improves production rates

- Prevents burning

- Extends tool life - reduces breakage

- Improves tolerance control

- Prevents smearing of metal or plastics

- Finished part is dry

- Eliminates wheel loading

- Low cost, no electricity

- Compact, lightweight, portable

- No moving parts - maintenance free

- Quiet - only 82 dBA

- No coolant cost

How the Cold Gun Works

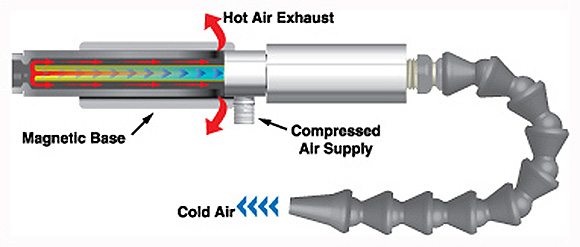

The Cold Gun incorporates a vortex tube to convert an ordinary supply of compressed air into two low pressure streams, one hot and one cold. The hot airstream is muffled and discharged through the hot air exhaust. The cold air is muffled and discharged through the flexible hose, which directs it to the point of use. The magnetic base provides easy mounting and portability.

The Compressed Air Supply

The Cold Gun is designed to use full line pressure of 80-100 PSIG (5.5-6.9 BAR). Temperature drop and flow are reduced when lower input pressures are applied. The use of clean, filtered air is essential to the operation of the Cold Gun. A manual drain filter that removes moisture, dirt and other particulates from the compressed air is included with each Cold Gun System.

Controlling the Cold Air

The EXAlR Cold Gun gives instant cold air when filtered compressed air is supplied to it. Cycling on and off is a good way to save air. For on and off control, use a Model 9012 Manual Shutoff Valve. To turn the Cold Gun on with the machine, the Model 9020 Solenoid Valve may be used and wired through the machine control switch. This method is ideal for hand grinders and drill sharpeners.

| Cold Gun Specifications | |||||

| Model | Pressure Supply | Air Consumption | Sound Level | ||

| PSIG | BAR | SCFM | SLPM | dBA | |

| High Power Cold Gun 5030 | 100 | 6.9 | 30 | 850 | 82 |