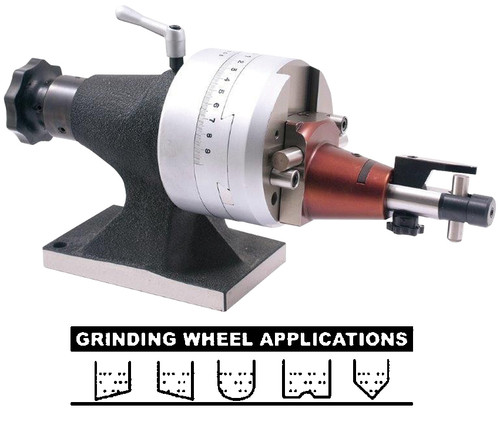

Motorized Brake Truing Dresser 3800-5251

How To: Mount the device with it’s wheel spindle parallel to the spindle of the straight wheel being trued.

For cylinder or cup wheels, mount perpendicular to their spindle. The correct wheel specification is determined by the grit size and bond type of the diamond wheel being trued.

Bring the diamond wheel and the truing wheel together until they almost touch. Turn on the diamond wheel (at normal grinding speed). At the point of contact, bring the two wheels together until they just touch. Be sure that the truing wheel is turning in the same direction as the diamond wheel. Switch on the Power Dresser.

The Power Dresser device is always used dry. Traverse the Power Dresser back and forth at 30 to 60 inches per minute. Downfeed .0005" to .001" at the end of each traverse. The truing wheel should run off the diamond wheel after each traverse to avoid chipping the edges of the diamond wheel. During the last few passes, reduce the downfeed to .00025" per pass.

When using the Power Dresser truing device, the only movement between the two wheels is traverse. Do not operate the work table on a rotary or reciprocating table traverse surface grinder.

When the truing operation has been completed, there will be a smooth, continuous contact and firing throughout each traverse stroke. Visual inspection of the diamond section will show an even appearance around the wheel. A reading with a dial indicator will show no runout.

This motorized power dresser is designed for the use of truing the periphery and face of larger diamond, CBN, and super abrasive wheels. It can be mounted on almost any grinding machine using wither a magnetic chuck table or mounted with screws to a fixture device. Constructed of cast iron and steel. It is rugged and durable.

- For exceptionally good finishes.

- This device operates at 120 RPM

- Power Supply: 110V/60Hz/ I Phase

- Dimensions: 105" x 5" x 3.5"

- Net Weight: 13 lbs